Quiet Power: The Science Behind Low-Noise Conveyor Belts

Low-noise conveyor belts may not sound like a game-changing innovation, but in reality, they’re reshaping everything from warehouse operations to food processing plants. Let’s explore the science behind these belts, and why they matter more than you think.

We often think of conveyor belts in terms of speed, strength, or durability. But there’s another factor that can make or break a system: noise. In factories, warehouses, gyms, and airports, the constant hum and rattle of a belt system can impact workers' health, customer comfort, and even energy efficiency. That’s why low-noise conveyor belts are more than just a nice-to-have, they’re a critical piece of smart engineering.

Why Noise Matters in Conveyor Systems

Excessive noises in industrial environments isn’t just an annoyance, they bring worker fatigue and stress, operational inefficiency and regulatory concerns.

Low-noise belting solutions might cost a little bit more, but as return they deliver real, measurable value:

- Improved Workplace Comfort – Creates a more pleasant, less stressful environment for employees.

- Longer Equipment Life – Reduced vibration means less wear on belts, pulleys, and bearings.

- Energy Savings – Smooth, low-resistance movement lowers energy consumption.

- Higher Productivity – With reduced noise and smoother handling, both operators and systems work more efficiently.

The Engineering Behind Low-Noise Belts

Reducing noise isn’t about simply softening a belt’s surface. It’s a deep, technical process involving material science, structural design, and mechanical precision. Here are some of the core innovations:

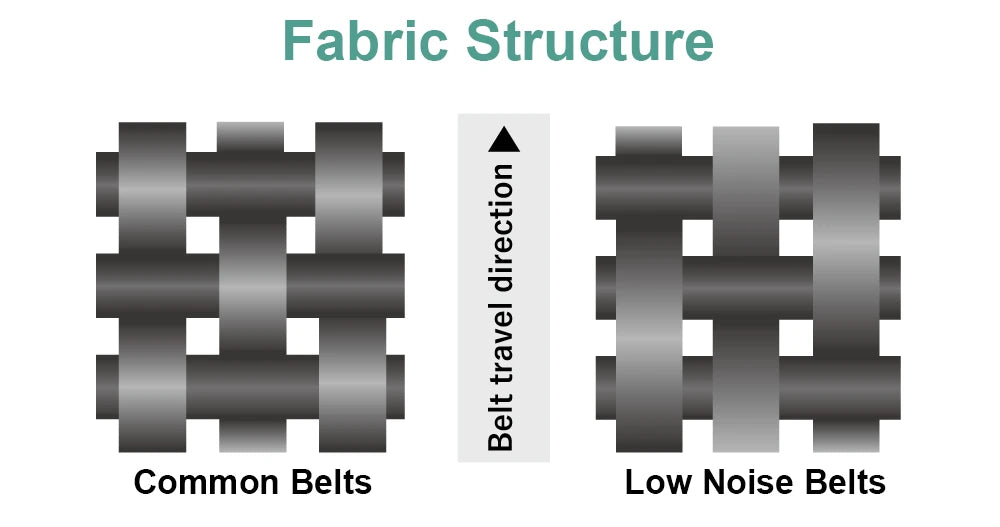

- Optimized Fabric Weave: Belts use tightly woven fabrics with uniform tension distribution. This prevents micro-vibrations that often create noise at higher speeds.

- Special Coatings: PVC, TPU, or hybrid coatings reduce surface friction and allow smoother contact with pulleys and rollers. Less friction equals less squeak and rattle.

- Precision Belt Geometry: Low-noise belts are engineered with consistent thickness and edge stability. This reduces the “slapping” sound when belts run at speed.

- Damping Layers: Some designs include built-in damping or cushion layers that absorb shock and reduce vibration transfer to the frame.

- Low-Noise Profiles: Surface profiles (like fishbone or golf) are re-designed to minimize air turbulence and contact noise without sacrificing grip.

Applications Where Noise Reduction Is Critical

Noise might not matter much in some environments, but in others, it’s a deal-breaker. Here’s where low-noise belts make the biggest impact:

- Warehouses & Distribution Centers: Quieter belts reduce worker fatigue and improve overall working conditions.

- Airports: Passengers expect smooth and quiet baggage handling—low-noise belts deliver exactly that.

- Fitness Equipment: Treadmill belts designed with noise control in mind create a better user experience and longer equipment life.

- Food Processing: In plants where hygiene and operator comfort matter, noise reduction contributes to a safer, calmer workplace.

Quiet Power, Strong Performance

At Kunming Conveyor Belt, we design conveyor belts that don’t just move products—they improve entire operations. Our low-noise solutions combine durability, efficiency, and acoustic performance, ensuring your line runs quietly, smoothly, and reliably.

Because sometimes, the most powerful performance is the one you hardly notice.

👉 Ready to upgrade your conveyor systems with low-noise solutions? Contact us today for expert advice tailored to your industry.