The Art and Science of Conveyor Belt Splicing: Techniques, how-to and Best Practices

Splicing is how two ends of one or two conveyor belts are joined to make one continuous loop. The quality of splicing directly impacts belt performance, lifespan, and safety. A perfect splice is invisible. You don't see it, you don't hear it, you just forget it's there. A bad one? It is a ticking time bomb that screams at you every shift.

What Really is a Splice? (Beyond the Basics)

Think of a splice not as a repair, but as a surgical graft. You are not just joining two ends; you're rebuilding the belt's backbone to be as strong as the original. Whether you're moving delicate pastries or crushing limestone, the principle remains: the splice is the linchpin of your entire operation.

Common Splicing Techniques

🔧 Mechanical Fastening: The “Get-You-By” Solution

- What it is: Metal hooks, plates, or staples punched through the belt.

- Advantages: Fast, simple installation, less equipment, minimal downtime.

- Best for: Emergency repairs, temporary setups, or low-tension applications.

- Limitations: It’s noisy, reduces belt life, and isn’t suitable for high-speed or food-grade environments.

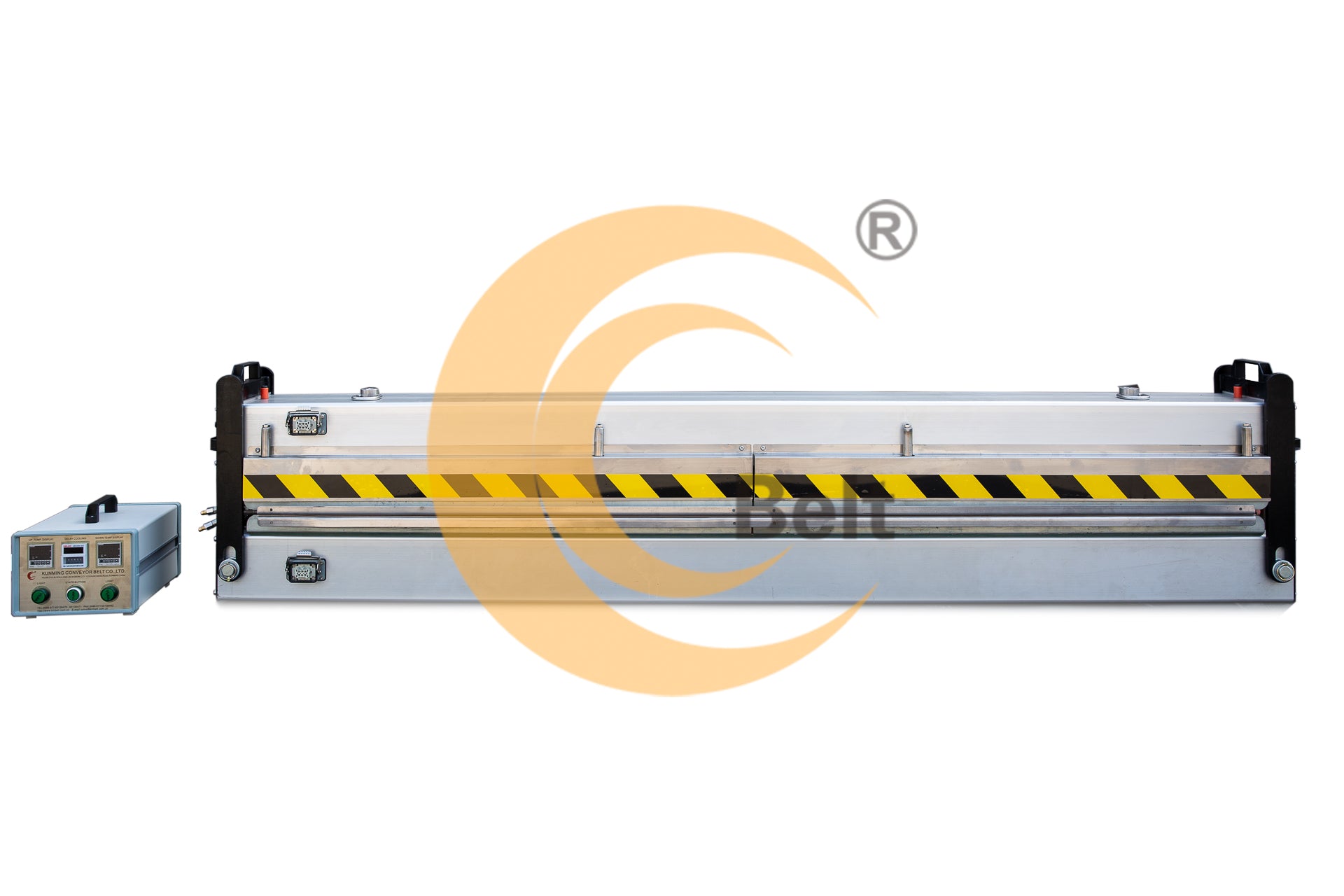

🔧 Hot Press Splicing: The Artisan's Method

This is the go-to method for permanent, strong, and seamless belt joints. Using heat and pressure, the belt ends are fused together in a splicing press.

Within this category, you’ll find a few different joint designs, each suited for particular applications:

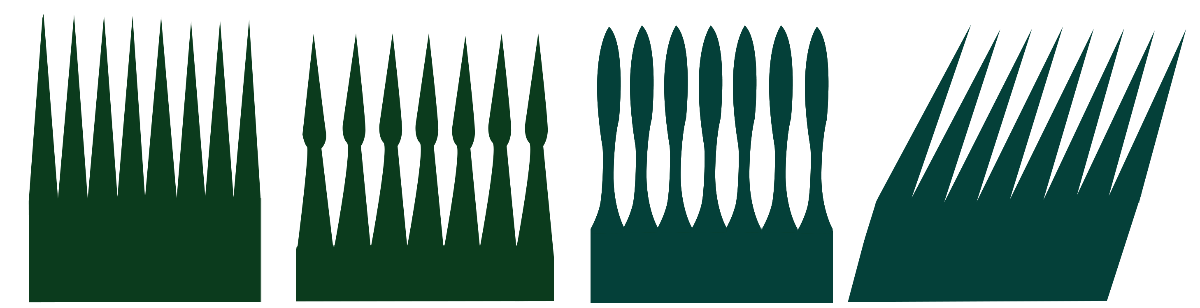

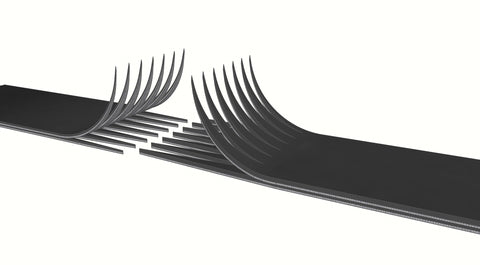

Finger Joint

The ends of the belt are cut into interlocking “fingers”. When pressed together under heat, they bond into a flexible and strong joint. Perfect for belts that bend around small pulleys.

Finger-Over-Finger Joint

Similar to the basic finger joint but with an extra finger layer. It gives you more strength and is great for belts that need to handle higher loads without compromising flexibility.

Step Joint

Imagine the belt ends cut like a staircase, with layers overlapping step by step. This creates a smooth, gradual transition that’s ideal for thicker belts. It helps reduce stress at the splice point.

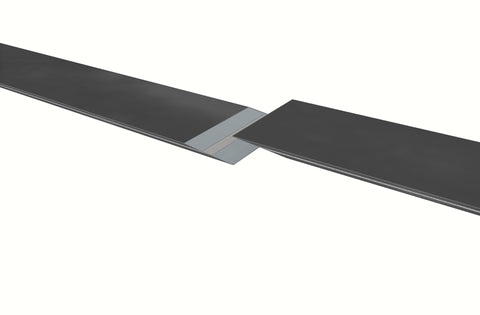

Skived Joint

Here, the belt ends are thinned (or “skived”) and overlapped before pressing. The result is a joint with uniform thickness across the belt- so it runs smoothly without creating a bump at the splice.

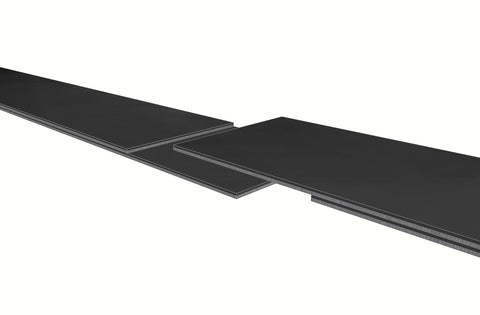

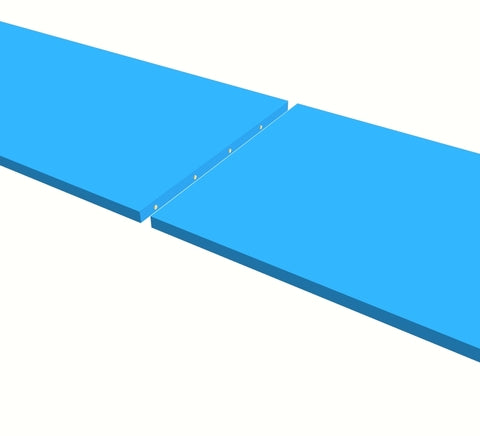

Butt Joint

The simplest of the bunch. The ends are cut straight, pressed together, and usually reinforced with a cover strip. It’s most often used for thin or homogeneous belts where a low-profile joint is essential.

What makes hot press splicing so effective is that, when done correctly, the splice can match or even exceed the belt’s original strength. It also gives you a smooth surface, which reduces noise, wear, and product damage.

Recommended Tools:

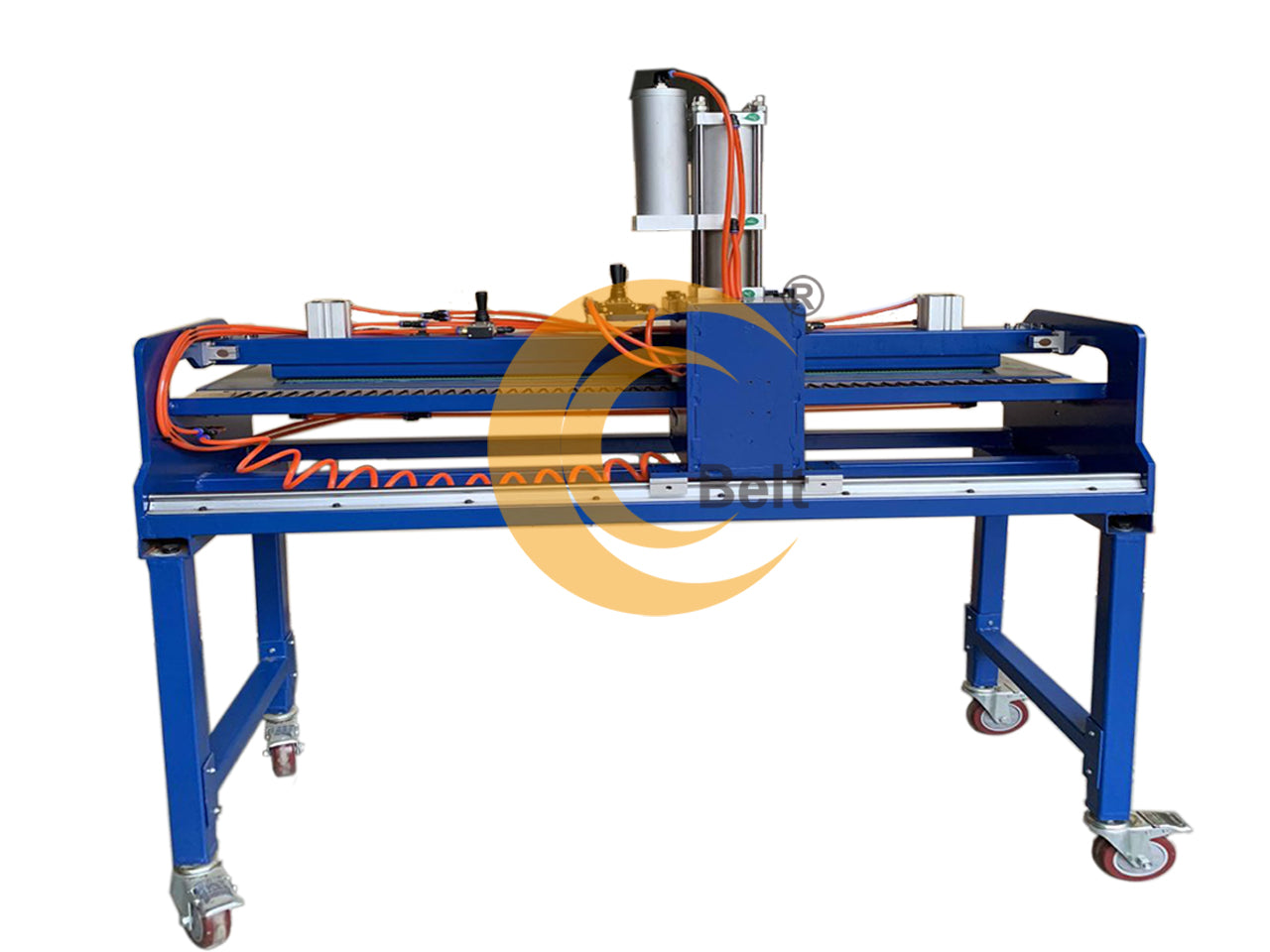

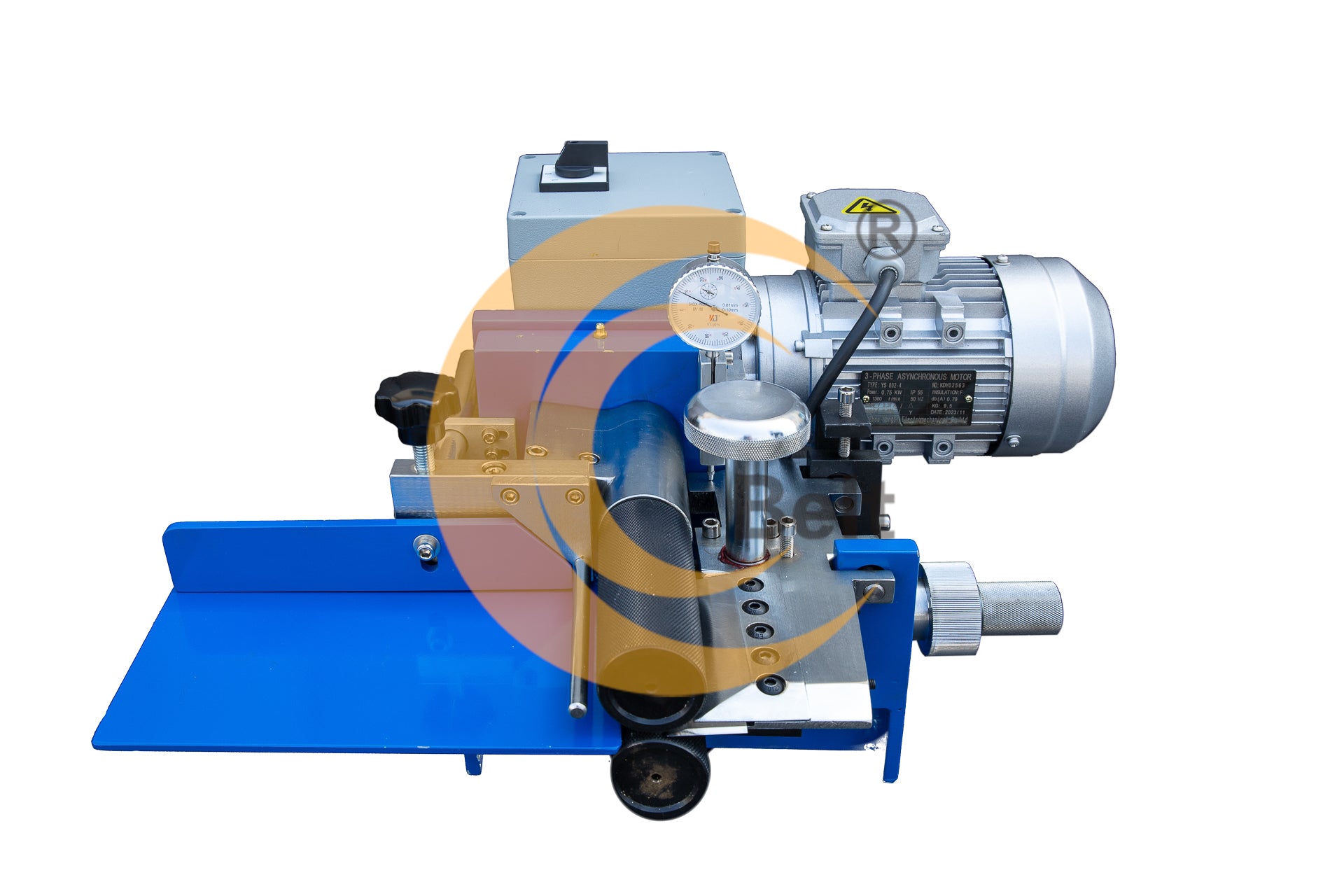

|

|

|

|

|

| Manual Finger Punchers | Pneumatic Finger Puncher | Ply Seperator /Splitter | Water Cooled Hot Press | Air Cooled Hot Press |

How to Splice Like a Pro

A successful splice isn't just about techniques - it's about precision and care. Here's what separates the pros from the amateurs:

- Cleanliness is Goodness: Even a speck of dust or oil can weaken the bond. Clean and tidy workspace and workpieces isn’t a suggestion; it’s a requirement.

- Measure Twice, Cut Once: Misaligned ends don’t just look bad—they cause tracking nightmares and premature wear.

- Respect the Recipe: Every belt material (PVC, TPU, rubber) has its own perfect cocktail of heat, pressure, and cure time. Follow your belt manufacturer’s instruction, while:

- Consider Your Environment - the Hidden Variables: The recipe parameters are not universal; they are influenced by the immediate working environment - High humidity can slow down the cure time, and cold ambient temperatures might require a longer heat application.

- Trial Before You Trust: The way to defeat this hidden variable is to conduct a trial splice, using off-cuts from your belt. It allows you to fine-tune the heat, pressure, and time parameters to discover the perfect "recipe" for your belt.

- Patience Pays Off: Give enough time till the splice fully cools and gets solid.

Best Practices for Reliable Conveyor Belt Splicing

- Always follow the belt manufacturer’s guidelines.

- Train staff regularly on splicing techniques.

- Invest in quality splicing equipment and materials.

- Inspect splices frequently as part of preventive maintenance.

- When in doubt, partner with a trusted conveyor belt supplier who offers technical support and splicing expertise.

Working With a Qualified Supplier Matters

At the end of the day, belts are only as good as the splice that holds them together. That’s why choosing the right partner is crucial.

A qualified conveyor belt supplier like Kunming Conveyor Belt doesn’t just sell you material and tools; they provide expert knowledge, guidance, and partnership. They’ll help you match the joint type to your application, avoid common mistakes, and maximize the life of both the belt and the splice.

When you work with Kunming Conveyor Belt, you’re not just buying a product - you're investing in reliability, efficiency, and peace of mind.

Ready to build unbreakable connections?